Page 2 of 3

Posted: Mon Dec 15, 2008 8:45 am

by mj43

A programmable ignition is on the cards (has been sat under my bed for the last 4 years) but I think I can squeeze a little more out of the stock system. Target is 35ftlb at 10600 which should equate to just under 70hp (a further 10% increase - about 76 on a Dynojet). When I get there then it will be time for more rpm. I am hoping this winters evolution should just about get there - probably miss by a mile but nothing ventured nothing gained

On more revs - I think the crank is strong enough to take another 1000 rpm it just needs more care in assembly and in particular balancing.

Posted: Mon Dec 15, 2008 10:08 am

by the-elf

Posted: Mon Dec 15, 2008 12:29 pm

by TwoStroke Institute

Ditching the waisted spark and using the progammable ignition will make you kick yourself you didn't convert 4 years ago.

The crank would benefit from a 90 deg phasing, the benefits are a massive reduction in the crank destroying rocking couple forces and corresponding increase in traction out of corners.

Latest ports have kept the main exhaust to the 60% mark with MASSIVE triangular sub exhaust ports. Septums between the transfers about 1.5mm wide. Don't forget the duct outlet.

Posted: Mon Dec 15, 2008 2:04 pm

by mj43

Interesting - I hadn't considered the 90deg crank. As my programmable is actually two separate units (no wasted spark) that is possible. Need to do some more thinking about that - would be very KTM then?

Can you explain what you mean by 60% I think I know just need to confirm.

KR has fairly large exhaust sub ports (biggest of any engine I have seen) -I can't easily make them triangular as there are inherent weakness' in the KR barrel and it would mean compromising reliability. A fair bit of work has gone into the KIPS ports. KR-1 barrels offer alternatives as they have more metal to start with.

Transfers are already as wide as can be made whilst maintaining reliability. Angles particularly of the rear transfer rear wall are of interest (not the boost port).

Lots of work on flow under the piston and into the transfer ducts - this is the main area I am working on. Looking at a long rod engine to give me more room in this area. Philosophy is that an engine is a pump and it is its efficiency as a pump that I need to work on initially. Resonances and pressure waves come later.

Posted: Tue Dec 16, 2008 9:42 pm

by dirk

Posted: Wed Dec 17, 2008 7:00 pm

by the-elf

Thanks Dirk, very interesting read.

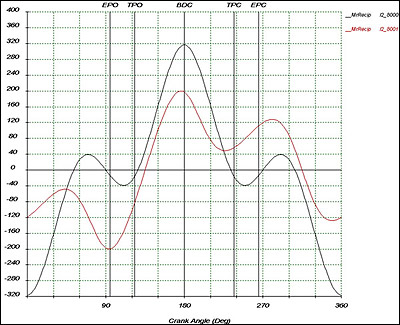

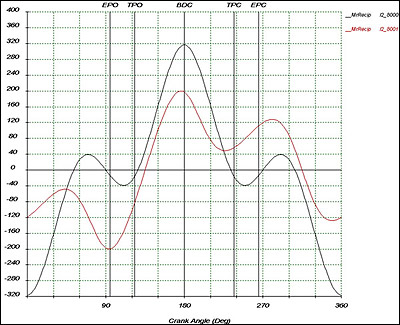

Port Map 90° crank vs 180 degree crank

Posted: Wed Dec 17, 2008 10:28 pm

by KR-1R

90° crank vs 180° cranks

The diagram below shows a 180° crank layout in the black trace and a 90° layout in the red trace. Here the lower rocking-couple peak forces inherent in the 90° layout can clearly be seen.

The 90° layout in a parallel-twin offers a reduction of peak rocking-couple forces of 31%, which is one of the reasons why KTM’s Technical Director Harald Bartol has chosen this layout for his team’s 250 FRR GP bike.

... the KR-1 is one of the few to run a balancer shaft for reducing perceived vibration issues.

90degree crank timings (BIGger bang engines) for rideability BLAH blah - sustaining traction, predictability of drive out of corners etc... If the destructive forces on the crank are reduced - crank and bearing life should be improved.

Note that the Rocking-Couple Peak Forces are independent of the crank’s Balance Factor. The Balance Factor is all about balancing the crank assembly precisely to match the reciprocating components, i.e. the piston/pin/rod etc, whereas the Rocking Couple relates to, in the case of a 180° parallel twin, the violent oscillation of the engine to the left and then to the right as opposing pistons reach TDC and BDC simultaneousl

====

Toroidal head inserts also bring spark plugs down lower in the combustion chamber, closer to where they need to be.

The result is a highly efficient combustion chamber that resists detonation and produces a more complete burn

...pinched from...

...pinched from...

http://www.twostrokeshop.com/two_stroke ... ngines.htm

Posted: Thu Dec 18, 2008 1:28 am

by TwoStroke Institute

Nice find Dirk, what book/magazine did that come from? 60-64% bore width(normaly standard width). A quick look at this

http://www.rgv250.co.uk/forums/index.ph ... opic=26089

shows how easy it is to gain 10hp in the mid range, much more than flow rates etc etc.

The balance shaft won't completely cancel the 180 deg rocking couple

forces mainly the vibrations that you feel when riding.YPVS 350 and stroker cranks a hopelessly balanced,that's what Steve is refering to there. The big advantage with the 90deg format is it mimicks a 90 deg V twin ie 1 piston is max deceleration(TDC/BDC) and the other is at max acceleration(mid stroke).

The torriod shape isn't what makes the difference but what the torriod allows you to do to the engine.There is an easy 1HP gain in proper race plus too.

Posted: Thu Dec 18, 2008 9:11 am

by Yatsushiro

TwoStroke Institute wrote:The big advantage with the 90deg format is it mimicks a 90 deg V twin ie 1 piston is max deceleration(TDC/BDC) and the other is at max acceleration(mid stroke).

Surely, at true mid stroke (when the small end, big end and crank centres create a 90° right angle), the piston speed is a maximum (from v=wr, where w is the rotational speed of the crank in radians/s), therefore the acceleration is zero ?

Posted: Thu Dec 18, 2008 10:25 am

by TwoStroke Institute

Maybe but doesn't eacape the fact that the 90 deg format is a winner.

Posted: Sun Dec 21, 2008 3:28 pm

by mj43

This is an interesting link

http://www.dinamoto.it/DINAMOTO/on-line ... /twin.html though it only considers the problem in the plane of rotation.

In fact the whole website is of interest

Posted: Mon Dec 22, 2008 7:43 am

by ScottaKR

My brain hurts now......

Made me realise I should've listened more in school.

Hell, I was stuggling to understand the pictures for goodness sake.... but from what little I could understand from them, it seems the best design (for reduced intertia) is the Boxer engine with the 180' crank, followed closely by the paralell twin with a 180' crank. The 90' paralell twin (or 270' depending on how you look at it) seemed to have a much greater amount of inertia acting against it, but that seems to go against what everyone here is saying.

Can someone explain this? am I missing something here (other than the patience to do the math myself that is

)?

Posted: Mon Dec 22, 2008 11:20 am

by TwoStroke Institute

From my reading of it the primary forces(blue arrow are easy to correct with matching of masses) the secondary forces(red arrow can't be cancelled out, so the crankpin angle and V angle are made to work with the engine not against it. The boxer and the 180 parralel twin have most forces centred around the Z axis(black dot coming out of the screen toward and away from you) which are not good.That's my reading I ask for a better clarification.Nice find mj.

Posted: Mon Dec 22, 2008 12:43 pm

by ScottaKR

TwoStroke Institute wrote:From my reading of it the primary forces(blue arrow are easy to correct with matching of masses) the secondary forces(red arrow can't be cancelled out, so the crankpin angle and V angle are made to work with the engine not against it. The boxer and the 180 parralel twin have most forces centred around the Z axis(black dot coming out of the screen toward and away from you) which are not good.That's my reading I ask for a better clarification.Nice find mj.

OK, thanks for that. So if someone was to change to a 90' crank, they would most likely need to adjust the timing and weight on the balance shaft to cancel out the primary inertia forces?

I don't get the Z-axis forces you mentioned. "(black dot coming out of the screen toward and away from you)"? Makes it sound like you've got a 3D monitor or something.

I thought the black dots simply represented the main crank journal and outer crank-pins.

Posted: Tue Dec 23, 2008 10:56 am

by TwoStroke Institute

There are some changes needed to the ignition for 90 deg, the balance shaft would become redundant as the rocking couple is vastly reduced.

X axis = horizontal

Y axis = vertical

Z axis = is at 90deg to both X & Y at the point of intersection.The black dot represents the crank centreline. The top graphic explains it.

I got some clarification on this and the red arrow that rotates is where a contra rotating balance shaft is installed.

The Boxer layout is very good as there are no primary/secondary forces as both pistons accelerate and decelerate at the same time.The Guzzi's secondary account's for their(in old Le Mans anyway) funny wobble at idle.