Page 3 of 5

Posted: Fri Aug 14, 2009 7:16 pm

by mj43

Said I would post what I have done to my KR started but not finished so this is a very unfinished doc. Tuning bit is the second part of the doc first bit was a start at providing info on stripping and building an engine.

http://myweb.tiscali.co.uk/teamsparrow/ ... sbuild.doc

Got any questions or queries and I will try and address them in the document

Posted: Sat Aug 15, 2009 8:58 am

by TwoStroke Institute

Just a small point you might like to check up on the "pipe step factor" but basicaly making the flange match the duct outlet will LOSE hp not gain it. It's a common mistake on NF/NX RS 125's and loses a quick 1-2HP.On a 37mm outlet I would be going 38.5mm min.

Posted: Sat Aug 15, 2009 9:21 am

by vincbr900

Posted: Sat Aug 15, 2009 10:14 am

by mj43

Yes I know about the h***a RS125 - had a '96 model.

I am sure the step in later models is larger than shown for the 92 and deliberate part of the casting in the floor of the exhaust port.

I believe that the problem stems from the fact that the exhaust port at that point shouldn't be round. On the KR in the exhaust port/flange area lower side there is Carbon build up indicating a dead gas (low flow) region.

Until I do that I will still match the port to the flange.

Posted: Sat Aug 15, 2009 3:11 pm

by TwoStroke Institute

I spend a lot of time welding up ducts on VMX cylinders and in every case a good step on the pipe to flange makes better mid range torque. I have never been able to put into words, why it works better. The NX has a oval outlet still with a step in it.That oval outlet and the straighter pipe is the main reasons why an NX has more hp than an NF.Same as the 'hump' in the duct floor which is sometimes removed.

I was trying for ages to find that website vince

Posted: Mon Aug 17, 2009 7:33 pm

by the-elf

mj43 wrote:Said I would post what I have done to my KR started but not finished so this is a very unfinished doc. Tuning bit is the second part of the doc first bit was a start at providing info on stripping and building an engine.

http://myweb.tiscali.co.uk/teamsparrow/ ... sbuild.doc

Got any questions or queries and I will try and address them in the document

Mark, what diameter are the oil holes in the cases to the main bearings?

Posted: Mon Aug 17, 2009 8:21 pm

by mj43

Same as standard about 3mm from memory. Try various drill bits in the stock cases till you find one that fits. The fun part is drilling through the filler in line with the stock hole

Posted: Mon Aug 17, 2009 8:42 pm

by mgtkr1

lol, oh yes!!! mine were drilled out to 4mm irc. i think std are only about 2mm but i cant swear to it. drilling requires bravery/nerve and memory(pre-filler)!!!!! satisfying though once completed. ive done 2 sets, my second are much improved over the 1st set of cases, very very close to the ones mark posted up in the flowed cases thread. the amount of irregularities in std cases is shocking. next to a sorted set the difference is unreal and becomes apparant just how much of an easier time the charge has getting to where it neds to be. for example on std cases look in the transfer area where the cases join. you will prob feel a ridge. same goes for the roof of the inlet where it parts and forms the path toward the transfers. another large obstacle.

Posted: Tue Aug 18, 2009 12:35 am

by falconman

About the oil hole in the transfer - I used a small plastic extension tube from a spray can, wrapped some tape on it (so it would be centered and a snug fit in the hole) then after the JB cured I drilled straight down the tube. Perfect alignment with no worries.

Posted: Tue Aug 18, 2009 10:31 pm

by mgtkr1

good idea, good fun this jb weld innit??? (not!!) horrid to use but bloody strong and the cases after the treatment give a real sense of satisfaction when comparing to std or cases flowed by mr stevens (essentially flowed a bit but still plagued with imperfections) desperatly need a good quality rotart tool/die grinder that will allow access into the transfers. any ideas?? foredom look ok but they seem to be sold in the us, not yet found a uk agent.

Posted: Wed Aug 19, 2009 2:00 am

by falconman

Foredoms are very good. Also very expensive. My unit (motor, pedal, pencil tool, 90 deg tool and the standard tool) cost about $1500US.

But if you can find a second hand setup the cost is less than half. You would also need a transformer as they are 110v. Not sure if they make a 220v version. FYI, I use my Dremel for most of my work. Only if I'm deep in the transfers do I break out the Foredom.

Posted: Wed Aug 26, 2009 1:40 am

by TwoStroke Institute

DO NOT WASTE YOUR MONEY ON FOREDOM TOOLS.

Get a CC Specialties tool if you want to be able to complete the job you started with the Foredom. Foredom motors are OK but hideously expensive.

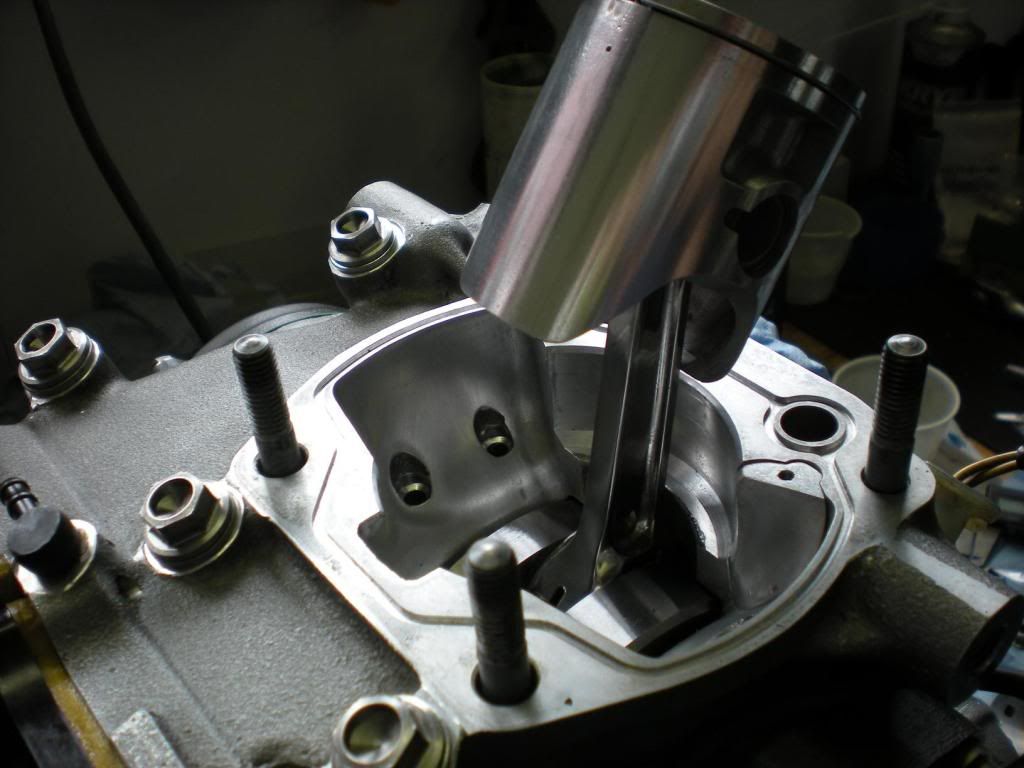

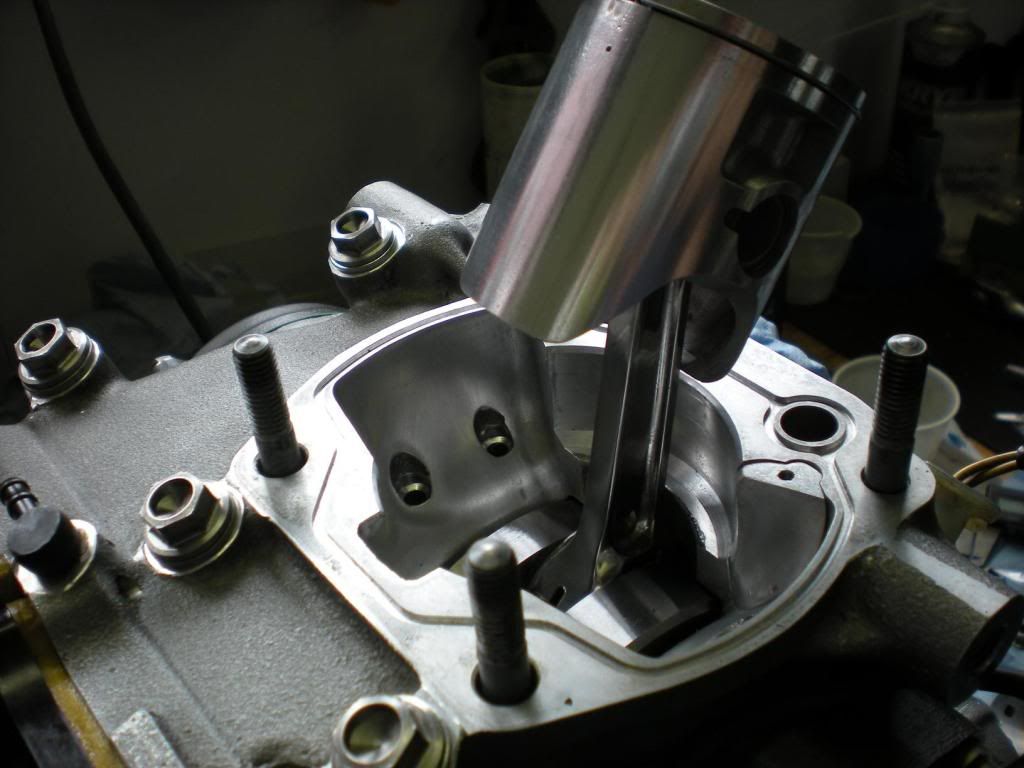

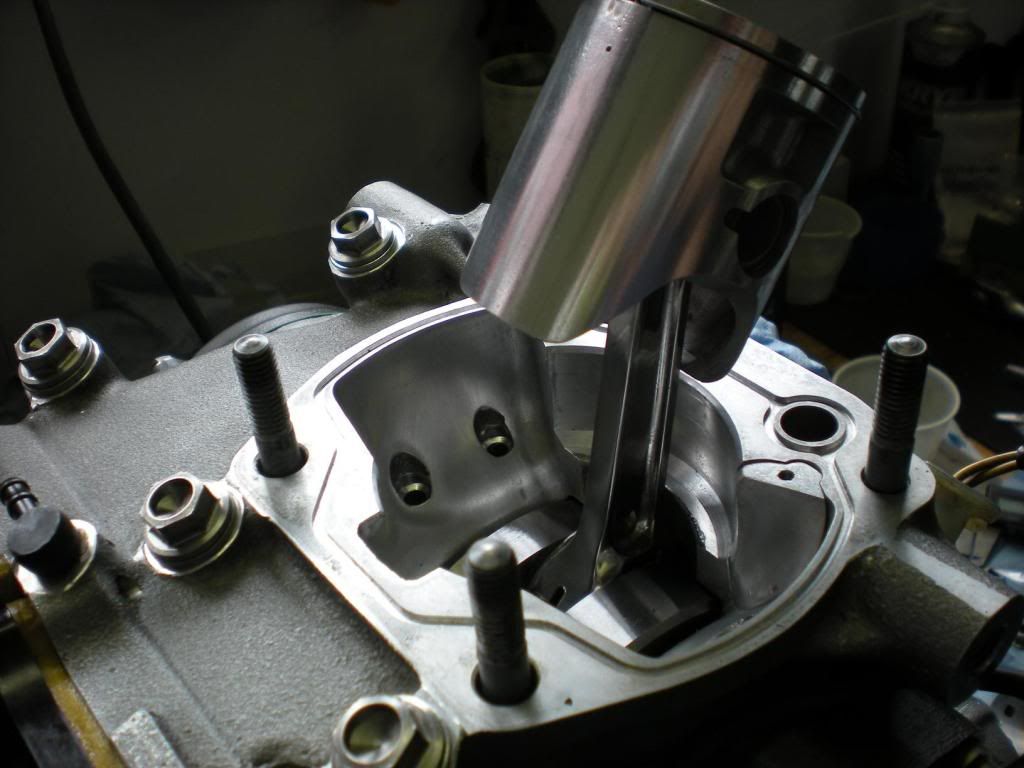

I'm not convinced that filling up the well makes one iota of difference to the performance of the engine.Here a genuine A-Kit h***a RS 250 engine has not 1 but 2 wells and they don't seem to lack any HP. BTW that is a Ti rod yours for a bargain of 8000Euro's

Posted: Wed Aug 26, 2009 7:10 am

by Sheik Yerbouti

I prefer air tools over all that flexi drive nonsense, try NSK or the like. Even Chicago pnuematic are not bad. Few other brands I cant think of for some reason...

http://www.nskamericacorp.com/prod_handTools.aspx

massive revs and small profile. I use em all the time for tooling work and engraving and I wouldnt piss on a dremel...

BTW is that some kind of removable block in that crankcase in left of pic lozza?

Posted: Wed Aug 26, 2009 8:32 am

by mj43

TwoStroke Institute wrote:DO NOT WASTE YOUR MONEY ON FOREDOM TOOLS.

Get a CC Specialties tool if you want to be able to complete the job you started with the Foredom. Foredom motors are OK but hideously expensive.

I'm not convinced that filling up the well makes one iota of difference to the performance of the engine.Here a genuine A-Kit h***a RS 250 engine has not 1 but 2 wells and they don't seem to lack any HP. BTW that is a Ti rod yours for a bargain of 8000Euro's

Bonneville bike was stock other than squish set to 0.8mm and cases worked on. That was worth an extra 6hp. Whilst no one bit of work to the cases contributes it is the sum of all the changes that gives that increase.

Posted: Wed Aug 26, 2009 9:08 am

by Sheik Yerbouti

Bonneville bike was stock other than squish set to 0.8mm and cases worked on. That was worth an extra 6hp. Whilst no one bit of work to the cases contributes it is the sum of all the changes that gives that increase.

Just out of curiosity, what was the squish before you set it up properly? Says a bit about production tolerances

Those holes where the wells are in that h***a pic are huge, is that for the extra bearing lube?