TwoStroke Institute wrote:What do you do if you only have a inertia dyno? Tell me more about the pressure transducers, I would love to look at these traces to see how closly they matched my simulated pressure/time histories.

If you just have an inertia dyne, you guess and hope.

IF you set them up (warm up the rollers, tyres, make sure the chain is tensioned for how tight you tie the bike down, tie the bike down tight enough so you can transmit the power but not so tight you develop excessive friction between the tyre and roller..... etc etc) then you can get ALMOST repeatable results. However I NEVER seen a dyne operator do this, and I have been to quite a few. They just do not have the time. (Time = money)

You need to do at least five repeats on any set up for a degree of confidence in the numbers you are generating. Each run on an inertia dyne takes a few seconds. This measure all the speeds you can think of. When I was running dynes each speed and load ran for a minute to stabilize it, a minute to collect the data then you go to the next point and repeat. You can burn dyne time like it is going out of fashion to do it right.

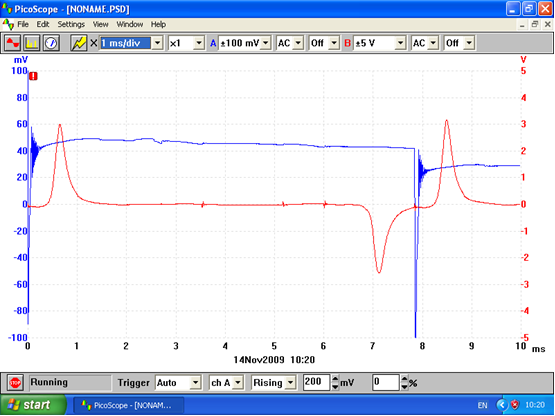

We should also clarify what detonation is and what it is not. You can hear det, you can see the results, the edges of the piston a plucked away and or the rings are clamped by the forces developed in the piston crown. When you blow a hole in centre, then this is pre-ignition usually seen when fuel quality is low or the compression ration is to high or the inlet temperature was higher than expected. You will never hear this. You can see it on the tip temperature of the spark plug and you can see it on a pressure trace (from a Kistler or similar) you may even be luck enough to shut it down before the crown melts (I never did) Usually when you see it go, it is too late and you have a ventilated crown....

I had a collection of about ten of those on my desk at one point, and the destroyed remains of three Kistlers to go with them.... When I was using them they were around UKP4000 each. Melted a charge amp lead on the exhaust as well....

Those det washers that h***a use are 'relatively' cheap in comparison, and as long as you calibrate them to a known cylinder then they will work as well as the Kistler. Some good software and Robert is related to you.

You could also use the 'knock' sensors found on pretty much most modern cars, but you will need to calibrate it, which will mean running at or very close to engine failure t make sure it is working ok. Mounted correctly they can be very good, mounted incorrectly they will be 'deaf' meaning your engine will blow up before they tell you it is about to....

They are only accelerometers so making the electronics to 'listen' to it is easy, how you make that interact with the ignition box is the tricky bit. To aggressive and the engine will never make power, not aggressive enough and it will fail.

None of this in my experience can be repeatably done on an inertia dyne.

Tips if you do go to the dyne. Watch how they set up someone else's before spending your cash.

Did they ratchet the bike down until the suspension collapsed?

Did they check the tyre pressure?

Did they check the chain still had slack in it when they ratcheted it down?

Did they make sure they at least tried to get some fresh air near where the intake is?

Did they ask how you had prepared the bike? (Water level, fuel, oil etc?)

Do they quote power numbers to 3 decimal places? (If they do, then walk away)

All the above shows that they at least have in inkling of what they are doing.

If you are there and the dyne hasn't been run for a while, did they warm the rollers up by either motoring them over or doing a few runs to get them hot. Remember the dyne is measuring the acceleration of the mass. Cold rollers accelerate slower than hot ones due friction in the bearings. This can massively affect the accuracy of the result.

Finally and this is another big clue to their competence, ask them what the maximum absorption their machine is. If they tell you it will handle 1000bhp and then strap your 60bhp bike to it and tell you it is plus or minus a horsepower, they have no clue about what they are doing.

Most inertia dyne's will measure to about 3% accuracy, some better some worse. 3% of 1000 is 30hp. The machine is simply not repeatable enough to know for certain if you made a change or if it was just dyne error.

Similarly a 100bhp machine will only measure to 3bhp, so if they tell you you are 1bhp better based on two runs, go somewhere else. You need skilled and consistent operators to get good results. Generally this does not happen for the less expensive dyne shops.

They are not really that much use for fuel mapping either, unless the dyne is set for the ACTUAL inertia of the bike and the rider. (I don't know of many that have variable inertia). The point with this is it takes energy to accelerate ALL parts of the bike including the engine and gearbox etc, and the fuel system is a dynamic. Go through a speed and load faster than you can on the bike on the road and the chances are the AFR you see on the dyne will be weak compared to the requirement. (This is generally true, but like all things, it depends....) go through too slowly and the opposite will be true. So if you have too much inertia (This generally does not happen, most inertia dynes are far too light for most bikes and rider combination) you will appear to be running lean. This is good for the dyne operator, the bike will not blow up on the road because he will richen it up to compensate, but not good for the customer. The bigger the difference between dyne inertia and real inertia, the greater the chances of error. A good operator will know this and compensate for it.....

Like anything you get what you pay for.

You can make a simple dyne yourself that will give repeatable results. All you need is a hydraulic pump, a method of recording pressure, a method of regulating pressure, and a good high speed data logging system and a computer.... Oh and a big open space to run it in where no-one will complain!

The results will be meaningless in terms of power numbers, unless you do some careful calibration, but you will be able to hold the engine at speeds and varying loads and see the effects of the changes you are making.

Crikey, I dribbled on there......