Page 7 of 7

Re: Hybrid project

Posted: Sat Jul 31, 2021 7:06 am

by maccas

I'm not sure carbon will be upto the job where it spigots into the bearing sleeves. The swingarm spindle will wear into the carbon (fretting), eventually increasing swingarm play. A better solution would be to use bearing sleeve with 20mm ID and simply have the carbon tube in between the two bearing sleeves. I appreciate this will cause some problems removing the sleeve from the swingarm. To be honest though, the carbon might wear even in that position, i'd be swapping it for aluminium instead.

Dan

Re: Hybrid project

Posted: Sat Jul 31, 2021 9:43 am

by Gerrit

So far I haven't found a bearing race with an ID of 20 mm and an OD of 28 mm, so that possible solution is out. I wouldn't be worried about fretting as the spindle and the sleeve are both stationary. I'd worry about the loads e.g. chain pull compressing the carbon fibre, which definitely would increase swingarm play. Might be just acceptable for a track/race bike if the carbon fibre tubes are inspected/replaced after each event, but not practical for a road bike.

Re: Hybrid project

Posted: Sat Jul 31, 2021 10:10 am

by maccas

They may be both stationary, but the swingarm spindle is still transmitting the driving, a portion of the weight of bike and braking forces through the frame. So the carbon sleeve will be loaded and unloaded millions of times in use. It's this that will cause the fretting. A steel spindle will wear through the carbon.

Regarding a bearing sleeve, getting some custom ones turned up and hardened would be the way to go. Won't be expensive as it's a simple shape.

Dan

Re: Hybrid project

Posted: Sun Aug 01, 2021 9:42 am

by Gerrit

Which is why the carbon fibre setup might be acceptable for a track/race bike which is stripped regularly with parts examined for wear, but not practical for a road bike unless the owner is willing to take the swingarm out regularly. Anyway, isn't all this experimenting fun? It adds to our practical knowledge base.

Re: Hybrid project

Posted: Mon Aug 02, 2021 8:23 am

by KR-1R

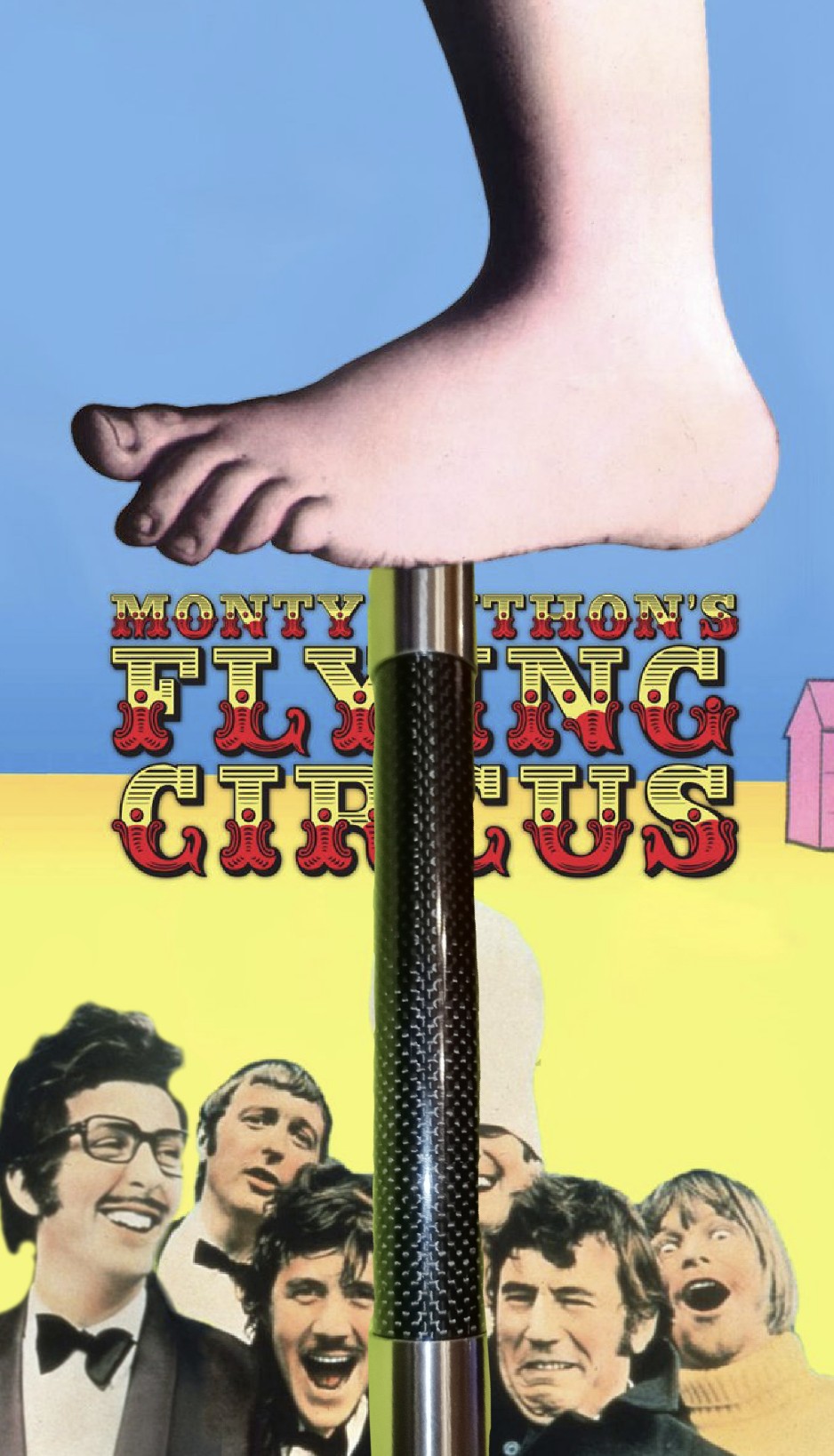

Whipped up a vacuum duct adapter nozzle for the dust.

Although slower it might be more accurate to hand finish

Printed tube collar/guide to help sand ends square

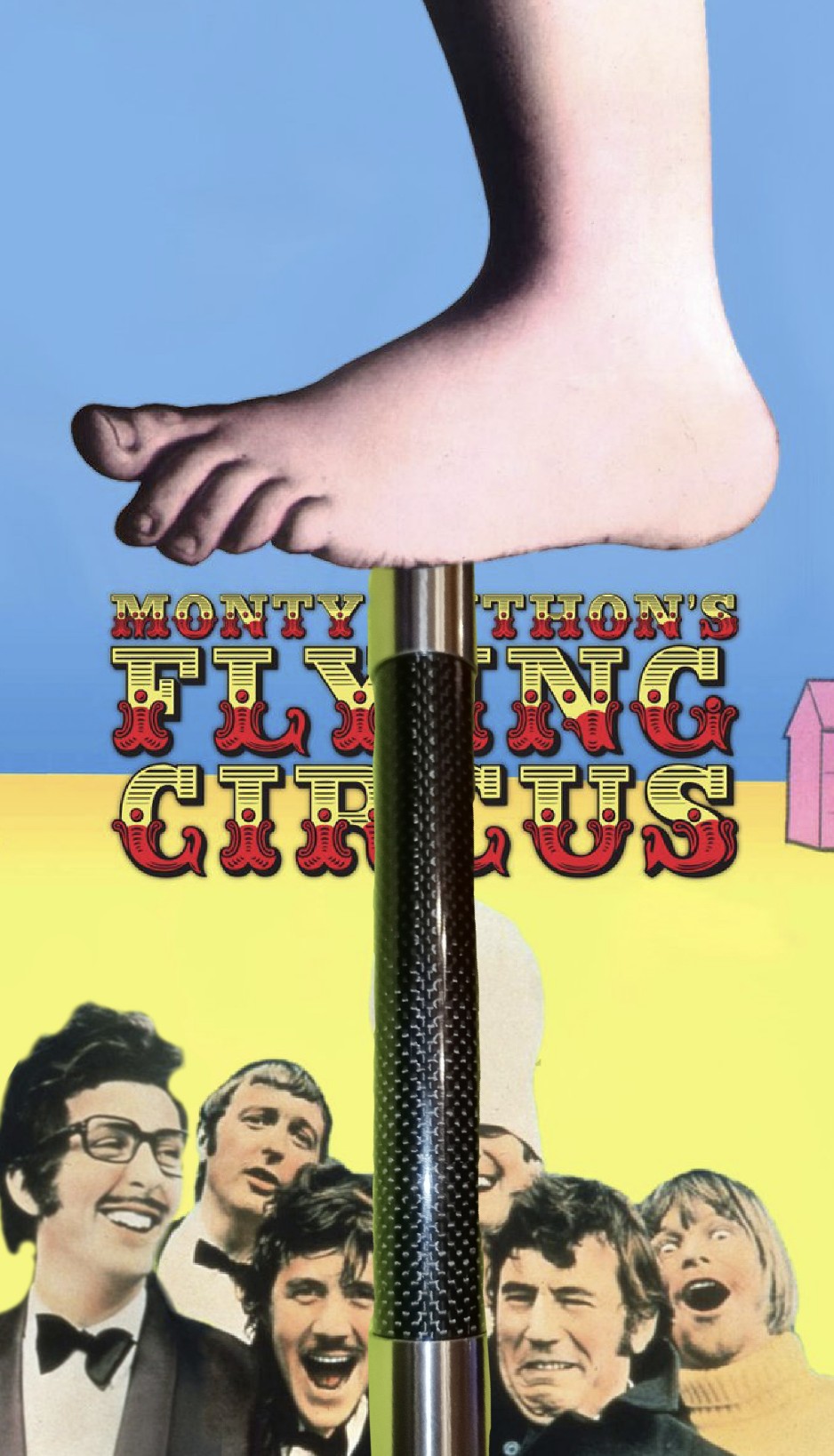

Magician's Wand

Posted: Tue Aug 03, 2021 6:20 am

by KR-1R

.

.

OEM swingarm sleeve 502g

Carbon compound sleeve 170g saving 66%

Re: Hybrid project

Posted: Tue Aug 03, 2021 8:10 am

by Gerrit

That's an impressive weight saving, better than my titanium contraption. Let's hope it works as well as it looks!

Re: Hybrid project

Posted: Tue Aug 03, 2021 9:35 am

by KR-1R

.

But your bearing idea

Re: Hybrid project

Posted: Tue Aug 03, 2021 1:45 pm

by maccas

Hope it works! Just keep an eye out for carbon dust when you strip it after using it for a while.

Sorry for being a negative Nancy. Just going off my experience with carbon fibre at work.

Nice one for trying something different (both you and Gerrit).

Dan

Re: Hybrid project

Posted: Tue Aug 03, 2021 4:26 pm

by Gerrit

I don't know what the clearance is between the 20 mm carbon fibre tube and the pivot bolt, but the clearance between the pivot bolt and my titanium spacer tube is about 0.05 mm which is significantly less that the rattle fit of the standard parts. This should reduce the swingarm play.

The only improvement I can suggest is bonding the two carbon fibre spacers together so the axial compression load is taken up by the full cross section area of 20 mm ID and 26 mm OD rather than just the 22 mm ID 26 mm OD spacer tube. Even better would be use of a 22 x 27 mm tube, but so far I haven't found such a size.