Some numbers needed

- scooble

- Premix Junkie

- Posts: 1549

- Joined: Thu Jul 27, 2006 12:47 pm

- Location: West Sussex

- Contact:

not sure if a temp sensor would respond fast enough for intermittent detonation, maybe you would also need to know what temperature the detonation starts. A small amount of detonation doesn't detroy the engine immediately and can be controlled by ignition advance, only when the compression is too high (or octane too low) will it actually start to runaway with itself even without a spark. Initially I used Bosch pieazo sensors, but even at 6k rpm on a 4 stroke it was still difficult to detect even through an acoustic filter, so a 2 stroke at twice the rpm would be very difficult indeed. The right kit makes the job sooo much easier, thats why I have so much respect for anyone who can do without it. I know HRC do them for RS125 and 250's but then again, they also have HRC prices to match

- smithyrc30

- Heavy Smoker

- Posts: 287

- Joined: Thu Oct 26, 2006 11:49 am

- Location: Torquay, Victoria, Australia

If you just have an inertia dyne, you guess and hope.TwoStroke Institute wrote:What do you do if you only have a inertia dyno? Tell me more about the pressure transducers, I would love to look at these traces to see how closly they matched my simulated pressure/time histories.

IF you set them up (warm up the rollers, tyres, make sure the chain is tensioned for how tight you tie the bike down, tie the bike down tight enough so you can transmit the power but not so tight you develop excessive friction between the tyre and roller..... etc etc) then you can get ALMOST repeatable results. However I NEVER seen a dyne operator do this, and I have been to quite a few. They just do not have the time. (Time = money)

You need to do at least five repeats on any set up for a degree of confidence in the numbers you are generating. Each run on an inertia dyne takes a few seconds. This measure all the speeds you can think of. When I was running dynes each speed and load ran for a minute to stabilize it, a minute to collect the data then you go to the next point and repeat. You can burn dyne time like it is going out of fashion to do it right.

We should also clarify what detonation is and what it is not. You can hear det, you can see the results, the edges of the piston a plucked away and or the rings are clamped by the forces developed in the piston crown. When you blow a hole in centre, then this is pre-ignition usually seen when fuel quality is low or the compression ration is to high or the inlet temperature was higher than expected. You will never hear this. You can see it on the tip temperature of the spark plug and you can see it on a pressure trace (from a Kistler or similar) you may even be luck enough to shut it down before the crown melts (I never did) Usually when you see it go, it is too late and you have a ventilated crown....

I had a collection of about ten of those on my desk at one point, and the destroyed remains of three Kistlers to go with them.... When I was using them they were around UKP4000 each. Melted a charge amp lead on the exhaust as well....

Those det washers that h***a use are 'relatively' cheap in comparison, and as long as you calibrate them to a known cylinder then they will work as well as the Kistler. Some good software and Robert is related to you.

You could also use the 'knock' sensors found on pretty much most modern cars, but you will need to calibrate it, which will mean running at or very close to engine failure t make sure it is working ok. Mounted correctly they can be very good, mounted incorrectly they will be 'deaf' meaning your engine will blow up before they tell you it is about to....

They are only accelerometers so making the electronics to 'listen' to it is easy, how you make that interact with the ignition box is the tricky bit. To aggressive and the engine will never make power, not aggressive enough and it will fail.

None of this in my experience can be repeatably done on an inertia dyne.

Tips if you do go to the dyne. Watch how they set up someone else's before spending your cash.

Did they ratchet the bike down until the suspension collapsed?

Did they check the tyre pressure?

Did they check the chain still had slack in it when they ratcheted it down?

Did they make sure they at least tried to get some fresh air near where the intake is?

Did they ask how you had prepared the bike? (Water level, fuel, oil etc?)

Do they quote power numbers to 3 decimal places? (If they do, then walk away)

All the above shows that they at least have in inkling of what they are doing.

If you are there and the dyne hasn't been run for a while, did they warm the rollers up by either motoring them over or doing a few runs to get them hot. Remember the dyne is measuring the acceleration of the mass. Cold rollers accelerate slower than hot ones due friction in the bearings. This can massively affect the accuracy of the result.

Finally and this is another big clue to their competence, ask them what the maximum absorption their machine is. If they tell you it will handle 1000bhp and then strap your 60bhp bike to it and tell you it is plus or minus a horsepower, they have no clue about what they are doing.

Most inertia dyne's will measure to about 3% accuracy, some better some worse. 3% of 1000 is 30hp. The machine is simply not repeatable enough to know for certain if you made a change or if it was just dyne error.

Similarly a 100bhp machine will only measure to 3bhp, so if they tell you you are 1bhp better based on two runs, go somewhere else. You need skilled and consistent operators to get good results. Generally this does not happen for the less expensive dyne shops.

They are not really that much use for fuel mapping either, unless the dyne is set for the ACTUAL inertia of the bike and the rider. (I don't know of many that have variable inertia). The point with this is it takes energy to accelerate ALL parts of the bike including the engine and gearbox etc, and the fuel system is a dynamic. Go through a speed and load faster than you can on the bike on the road and the chances are the AFR you see on the dyne will be weak compared to the requirement. (This is generally true, but like all things, it depends....) go through too slowly and the opposite will be true. So if you have too much inertia (This generally does not happen, most inertia dynes are far too light for most bikes and rider combination) you will appear to be running lean. This is good for the dyne operator, the bike will not blow up on the road because he will richen it up to compensate, but not good for the customer. The bigger the difference between dyne inertia and real inertia, the greater the chances of error. A good operator will know this and compensate for it.....

Like anything you get what you pay for.

You can make a simple dyne yourself that will give repeatable results. All you need is a hydraulic pump, a method of recording pressure, a method of regulating pressure, and a good high speed data logging system and a computer.... Oh and a big open space to run it in where no-one will complain!

The results will be meaningless in terms of power numbers, unless you do some careful calibration, but you will be able to hold the engine at speeds and varying loads and see the effects of the changes you are making.

Crikey, I dribbled on there......

-

TwoStroke Institute

- Oil Injector

- Posts: 505

- Joined: Sat Jul 05, 2008 2:17 pm

Deto is easy to detect and there is no fire to really burn you putting on an another ignition. Playing around when you have no idea what your doing it what hurts.

An under plug thermocouple and egt gauges will pick up the on set of deto no problems, if they rise and fall together all is good.If one rises the other starts to fall grab the clutch fast. Nearly all the readily available thermocouples I've ever used have had a fast enough repsonse time to spot this. A safe EGT

(depends on compression ratio) for a water cooled engine is 1200 deg F at the the end of a full throttle pull and I normaly work to 200deg C on CHT.

The HRC system is cheap as you just have to know where to look I got to 125 counters and looms and sensors for sub $500.Only the 3-5 dets per km changes for a 56mm bore.

There is a very common theme with every published two stroke curve I have seen, they nearly all run the same advance at peak power.

Have used a variation(shifting to the left 1000rpm) of the TZ curves I put a link to on a few occasions without any drama's.

Programming a curve is nowhere near as hard or as dangerous as being made out. Similar to the fear of rejetting

An under plug thermocouple and egt gauges will pick up the on set of deto no problems, if they rise and fall together all is good.If one rises the other starts to fall grab the clutch fast. Nearly all the readily available thermocouples I've ever used have had a fast enough repsonse time to spot this. A safe EGT

(depends on compression ratio) for a water cooled engine is 1200 deg F at the the end of a full throttle pull and I normaly work to 200deg C on CHT.

The HRC system is cheap as you just have to know where to look I got to 125 counters and looms and sensors for sub $500.Only the 3-5 dets per km changes for a 56mm bore.

There is a very common theme with every published two stroke curve I have seen, they nearly all run the same advance at peak power.

Have used a variation(shifting to the left 1000rpm) of the TZ curves I put a link to on a few occasions without any drama's.

Programming a curve is nowhere near as hard or as dangerous as being made out. Similar to the fear of rejetting

crochet & croquet

- smithyrc30

- Heavy Smoker

- Posts: 287

- Joined: Thu Oct 26, 2006 11:49 am

- Location: Torquay, Victoria, Australia

The playing around when you don't know what to do only really hurts your bank balance.TwoStroke Institute wrote:Deto is easy to detect and there is no fire to really burn you putting on an another ignition. Playing around when you have no idea what your doing it what hurts.

Snipety snip....

Programming a curve is nowhere near as hard or as dangerous as being made out. Similar to the fear of rejetting

While detecting detonation is relatively easy, the what to do next is not so easy. Shutting the throttle usually works but the sudden lean out caused can send the temperature through the roof and kill the cylinder just as easily. Similarly pulling in the clutch works most times, but if the spark plug temperature (that is the electrode temperature) is close to its limit, you can quite easily kill the piston with that. (I've done that

Programming a curve into an ignition system even bending an existing one to do something different is easy. Getting it to work in harmony with all the other mods is the hard bit.

I made my own ignition to work on my racer, fully adjustable curves and all that, however getting the correct numbers so it worked well with everything else was a bit more involved and a lot more expensive.

I think what was being said was if it were cheap and easy, every engine would run perfectly every time and all our bikes would cost about half as much as they do and develop twice the power they do. They don't because it isn't.

I doubt it is fear that holds people back from doing it, more likely cost. The 250GP bikes do not get 100ps+ by luck, there is a lot of hard work, long hours and expensive dyne time in those engines.

-

TwoStroke Institute

- Oil Injector

- Posts: 505

- Joined: Sat Jul 05, 2008 2:17 pm

This is the FEAR I'm talking about.

We don't need to make our own ignitions, they come with pre-programmed curves and there are perfect curves people are kind enough to put on their websites just waiting to be applied.

It's easy to get things to work i harmony just buy MOTA.

We don't need to make our own ignitions, they come with pre-programmed curves and there are perfect curves people are kind enough to put on their websites just waiting to be applied.

It's easy to get things to work i harmony just buy MOTA.

crochet & croquet

-

mj43

- Premix Junkie

- Posts: 1329

- Joined: Tue Jul 25, 2006 7:44 pm

- Location: Middle England

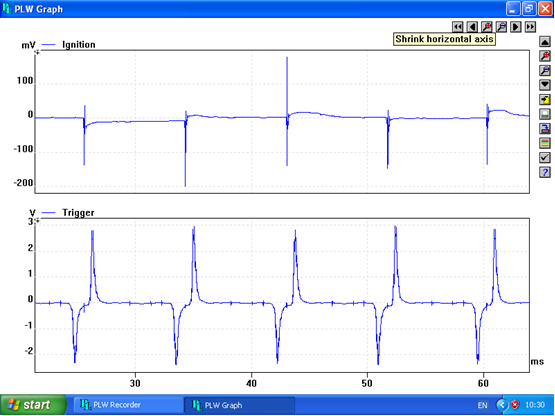

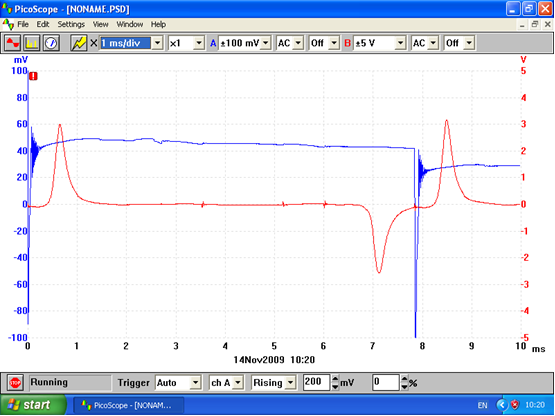

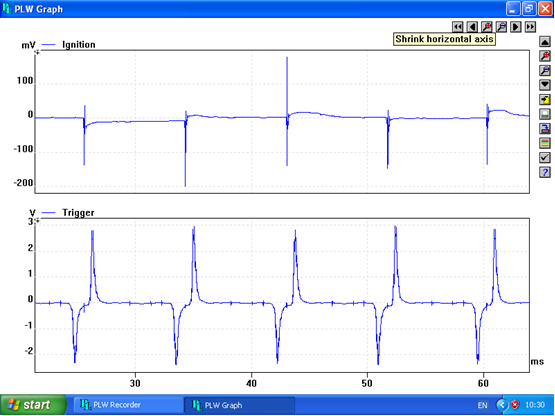

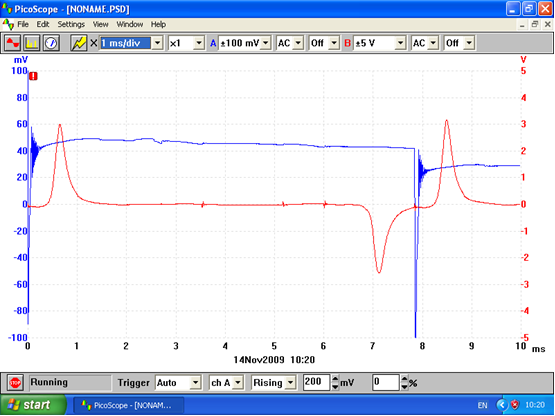

OK not sure the neighbours appreciated it but first run just to see how it works.

Screen grab from the data logger output (above) and screen grab off the scope below. Need to work out RPM as I wasn't watching the tacho (not that it tells the truth). Bit of work to do now on the processing and then I will go for a full RPM run tomorrow - possibly. Not sure if neighbours will appreciate a KR running up to 12,000 rpm on a Sunday morning

Red trace is the trigger - negative going spike is when the raised edge on the rotor gets to the pickup, positive spike as it leaves. Blue trace is off the HT lead.

Screen grab from the data logger output (above) and screen grab off the scope below. Need to work out RPM as I wasn't watching the tacho (not that it tells the truth). Bit of work to do now on the processing and then I will go for a full RPM run tomorrow - possibly. Not sure if neighbours will appreciate a KR running up to 12,000 rpm on a Sunday morning

Red trace is the trigger - negative going spike is when the raised edge on the rotor gets to the pickup, positive spike as it leaves. Blue trace is off the HT lead.

-

TwoStroke Institute

- Oil Injector

- Posts: 505

- Joined: Sat Jul 05, 2008 2:17 pm

It's probably over simplistic but why noy just mark off 2deg increments on the flywheel and use one of THESE to check advance?

With any programmable igntion you MUST complete this process first. Measure the base advance from either the middle of the trigger bar to TDC or the end of the trigger to TDC(depnding on what the manual says) then program in a straight line fixed advance, mark off on the rotor the corresponding amount of deg BTDC to what you programmed(say 15deg), then with you timing light check if your reference mark is before of after what you have programed. You can then use the compensation to get the 2 marks aligned. Not sure if I explained that well enough but it's what you have to do before you start punching numbers in.

With any programmable igntion you MUST complete this process first. Measure the base advance from either the middle of the trigger bar to TDC or the end of the trigger to TDC(depnding on what the manual says) then program in a straight line fixed advance, mark off on the rotor the corresponding amount of deg BTDC to what you programmed(say 15deg), then with you timing light check if your reference mark is before of after what you have programed. You can then use the compensation to get the 2 marks aligned. Not sure if I explained that well enough but it's what you have to do before you start punching numbers in.

crochet & croquet

-

mj43

- Premix Junkie

- Posts: 1329

- Joined: Tue Jul 25, 2006 7:44 pm

- Location: Middle England

You could but it has its limitations

How do you measure RPM? Don't say Tacho the stock tacho is at least a 1000 rpm out at 10,000. Though I think you can get guns with a tacho built in.

Accuracy is limited to a few degrees.

I have heard some cheap ignitions suffer jitter - would you see that with a timing light?

System I am working on should work on any ignition including ones where the advance changes as a function of crank acceleration (told TZ ignitions circa 1996 do that). You can't measure that with a lamp as you can only do steady rpm.

My method admittedly more complicated should be much more accurate and more flexible.

How do you measure RPM? Don't say Tacho the stock tacho is at least a 1000 rpm out at 10,000. Though I think you can get guns with a tacho built in.

Accuracy is limited to a few degrees.

I have heard some cheap ignitions suffer jitter - would you see that with a timing light?

System I am working on should work on any ignition including ones where the advance changes as a function of crank acceleration (told TZ ignitions circa 1996 do that). You can't measure that with a lamp as you can only do steady rpm.

My method admittedly more complicated should be much more accurate and more flexible.

-

mj43

- Premix Junkie

- Posts: 1329

- Joined: Tue Jul 25, 2006 7:44 pm

- Location: Middle England

OK a very draft set of results not to be used as I still have to do some checks and redo a number of measurements that I am not happy with. Also my routines for event detection need tidying up. If the data is to be believed the ignition takes about 20microseconds for voltage to build up to the point that a spark occurs. This is about 1.5 degrees at 12000 rpm.

Jitter in the results is caused by my event detector not always being consistent when the data is noisy. Also found calculating RPM isn't as easy as I thought. Over 1 revolution a crank slows down and speeds up so depending on which events I use to calculate the RPM I get a spread of results. These I believe are due to both the crank speeding up and slowing down and my event detection.

Anyway - results as a first pass don't look daft. KR curve looks very simple compared with RGV. Basically flat at about 25degrees up to about 7600rpm and then a flat slope down. Compared with curves posted on the RGV forum it seems very conservative.

As mentioned this is a first pass so please don't go programming ignition systems on the basis of this curve. Green bit is an extrapolation - no idea what the actual curve does there yet

Just looked up the manual - says 25degrees to 7500rpm

Jitter in the results is caused by my event detector not always being consistent when the data is noisy. Also found calculating RPM isn't as easy as I thought. Over 1 revolution a crank slows down and speeds up so depending on which events I use to calculate the RPM I get a spread of results. These I believe are due to both the crank speeding up and slowing down and my event detection.

Anyway - results as a first pass don't look daft. KR curve looks very simple compared with RGV. Basically flat at about 25degrees up to about 7600rpm and then a flat slope down. Compared with curves posted on the RGV forum it seems very conservative.

As mentioned this is a first pass so please don't go programming ignition systems on the basis of this curve. Green bit is an extrapolation - no idea what the actual curve does there yet

Just looked up the manual - says 25degrees to 7500rpm

Last edited by mj43 on Mon Nov 16, 2009 10:39 pm, edited 1 time in total.

- smithyrc30

- Heavy Smoker

- Posts: 287

- Joined: Thu Oct 26, 2006 11:49 am

- Location: Torquay, Victoria, Australia

I'm not sure there is a 'generic' super ignition curve that fits all engine configurtions.TwoStroke Institute wrote:This is the FEAR I'm talking about.

We don't need to make our own ignitions, they come with pre-programmed curves and there are perfect curves people are kind enough to put on their websites just waiting to be applied.

It's easy to get things to work i harmony just buy MOTA.

If there was why wouldn't all the engines in the world be using it?

When I made my own ignition, there weren't firms making this stuff for sale. The best options were Motoplat and Boyer Brandsen. Neither of them did what mine did. Neither was programable. This was 1984.... The glourious days of proddy 250LC racing.

Buying MOTA is not the end of it. I have a copy of this. I have a selection of Matlab/Simulink models produced from Blair's work. I've got some stuff from QUB from an old colleague of mine. Putting the same stuff in yields different resluts (as you would expect) but more importantly changes affect each model's answers in different manners.

I don't think you can just believe what one model tells you and assume it is right or perfectly harmonious.

- smithyrc30

- Heavy Smoker

- Posts: 287

- Joined: Thu Oct 26, 2006 11:49 am

- Location: Torquay, Victoria, Australia

I agree with you, the timing light is open to many accuracy questions, paralax being the most consistent source of error.mj43 wrote:You could but it has its limitations

How do you measure RPM? Don't say Tacho the stock tacho is at least a 1000 rpm out at 10,000. Though I think you can get guns with a tacho built in.

Accuracy is limited to a few degrees.

I have heard some cheap ignitions suffer jitter - would you see that with a timing light?

System I am working on should work on any ignition including ones where the advance changes as a function of crank acceleration (told TZ ignitions circa 1996 do that). You can't measure that with a lamp as you can only do steady rpm.

My method admittedly more complicated should be much more accurate and more flexible.

These things have not output for data logging and there is the unknown electronic delay for them.

Your method is by far better.

Incidentally, the inconsistency you see with triggering could be due to the selection of too hig a voltage as the trigger.

VR sensors have latency issues which get more significant with speed. If your trigger voltage is too near the nominal you will get false triggering.

The scatter that you have plotted looks fairly normal for instabilty in triggering.

You should also remember each cycle is differnt, so you will get some inconsistanct from that too.

Are you triggering from the falling or leading edge?

-

mj43

- Premix Junkie

- Posts: 1329

- Joined: Tue Jul 25, 2006 7:44 pm

- Location: Middle England

In data acquisition mode the logger just grabs data at a pre-selected rate so no triggering involved. Data captured at ~10microseconds per sample for first trial - so resolution is about a 0.5 degree at max rpm. I can grab faster but the unit only has a 32k buffer. The gaps in the data are where unit was emptying buffer to the PC and I didn't revisit that bit of the rpm curve when data logger was grabbing.

System grabs, stops stores, grabs etc. At the moment it is all Excel based so probably could be made faster. User sets how many grabs per run up to 80. Users needs to go up and down the rev range a few times to ensure a full capture. Downside, or it could be upside with a bit more processing, is that you get data for acceleration and deceleration and hence as it works at the moment two different RPM for the same trigger point.

Only takes a few seconds but even though I warned the neighbours I didn't think it fair to run an engine flat out for too long on a Sunday

System is based on a Pico 212/3. Looking at equivalent systems, prices have gone through the roof but they do offer up to 1MB buffer. Chinese copies on E-Bay are cheaper but have smaller buffers. Another problem I have is that it is a parallel port system and the only lap top I have with a parallel port is an old Thinkpad with 370MB of RAM running XP. XP has such an overhead even when stripped down the 'puter can barely fire up let alone support any other application. After a data run it takes 10minutes to populate the spreadsheet. Sure it would be better on a faster PC

A few more winter nights and I reckon I can sort the bugs and have a slick logging system.

Next trial is in a few weeks when I take the KR over to James' dyno to test the programmable.

Hopefully also log a '92 TZ ignition on the same visit.

System grabs, stops stores, grabs etc. At the moment it is all Excel based so probably could be made faster. User sets how many grabs per run up to 80. Users needs to go up and down the rev range a few times to ensure a full capture. Downside, or it could be upside with a bit more processing, is that you get data for acceleration and deceleration and hence as it works at the moment two different RPM for the same trigger point.

Only takes a few seconds but even though I warned the neighbours I didn't think it fair to run an engine flat out for too long on a Sunday

System is based on a Pico 212/3. Looking at equivalent systems, prices have gone through the roof but they do offer up to 1MB buffer. Chinese copies on E-Bay are cheaper but have smaller buffers. Another problem I have is that it is a parallel port system and the only lap top I have with a parallel port is an old Thinkpad with 370MB of RAM running XP. XP has such an overhead even when stripped down the 'puter can barely fire up let alone support any other application. After a data run it takes 10minutes to populate the spreadsheet. Sure it would be better on a faster PC

A few more winter nights and I reckon I can sort the bugs and have a slick logging system.

Next trial is in a few weeks when I take the KR over to James' dyno to test the programmable.

Hopefully also log a '92 TZ ignition on the same visit.

- smithyrc30

- Heavy Smoker

- Posts: 287

- Joined: Thu Oct 26, 2006 11:49 am

- Location: Torquay, Victoria, Australia

Ah I see, I looked at the Pico web site, first time I've seen their stuff.

I see they do a parallel to USB converter, not sure if they would help with the computing side of it?

I wandered around some of their stuff. Some the claims are a bit hard to swallow. (e.g. 0.001deg measurement capability on all sorts of thermocouples, most of which have a +/-1deg accuracy).

The stuff looks well made and seems to function well enough given the limits of the laptop you have to use.

Keep up the good work.

I see they do a parallel to USB converter, not sure if they would help with the computing side of it?

I wandered around some of their stuff. Some the claims are a bit hard to swallow. (e.g. 0.001deg measurement capability on all sorts of thermocouples, most of which have a +/-1deg accuracy).

The stuff looks well made and seems to function well enough given the limits of the laptop you have to use.

Keep up the good work.