Page 1 of 1

help please! cylinder head confusion

Posted: Wed Oct 08, 2008 7:04 pm

by dirk

hi folks,

my english is bad, but i try to explain because i am helpless with this fu... head.

ok short story

head was warped.

My machinist has skim the head around 0,5mm.

After this there was no edge round the combustion chamber an the squish was to less (~0,6mm).

i am told him that the squish band must recessed into the head by 0.4mm and angled at 15 degrees.

I thought a squish clearance around 1mm is safe.

today he has finished the work.

ok at home i measure the diameter from the combustion chamber (edge to edge).

The diameter is exactly 56mm.

the piston has 55,6mm.

my old destroyed head has an combustion camber diameter from ~57,5mm !!

ok my questions.

why is the diameter from the standard head combustion chamber much bigger then the cylinder bore diameter?

can i use the head with 56mm?

the head skim was 0,5mm.

to much compression now?

ok i know... many questions and perhaps some stupid questions.

I have a new crank, new coated cylinders and new pistons.

i have no interest to destroy the engine with a bad cylinder head....

[-o<

thanks

dirk

kr1s... what an bike.

i think sometimes i sell this bike.

Posted: Thu Oct 09, 2008 10:03 am

by scooble

From my understanding, the combustion area of the head should have a diameter that is the same as the cylinder i.e. 56mm.

If you took 0.5mm from a standard head, your squish would PROBABLY be Ok, however, you need to measure this. Its quite easy, poke a piece of solder wire in to the cylinder via the spark plug hole and trap it between the piston and the head by gently turning the engine over with the kickstarter by hand. Remove the squashed solder wire and measure with a set of vernier calipers. 0.8mm is about right and as Elf said, anything below this is getting a bit close. Do this for the front, back and left and right of each cylinder. Reducing the squish only has only a moderate effect on the compression ratio and does not require higher octane fule. I did this for mine and it was fine - so you 'should' be Ok.

Posted: Thu Oct 09, 2008 4:50 pm

by the-elf

Scooble is correct but do all four positions together to compensate for piston rock. your squish should be about 0.8mm. The reason why the old cylinder head was different diameter was probably down to crap maching tolerences.

The angle of the squish band should be a bit more than a tangent from the domn of the piston, this is to push the unburnt fuel back into the centre of the chamber.

Posted: Sat Oct 11, 2008 9:41 pm

by dirk

hi

thanks for your help.

the squish clearance and bore diameter should be now ok.

it is ~0,9mm.

next big problem...

the head leak again after few seconds.

left and right hand.

i have tried two times.

first with an used genuine head gasket and a little bit "DIRKO HT" (silicone sealer).

do not work -> leak

second a new not genuine head gasket -> leak

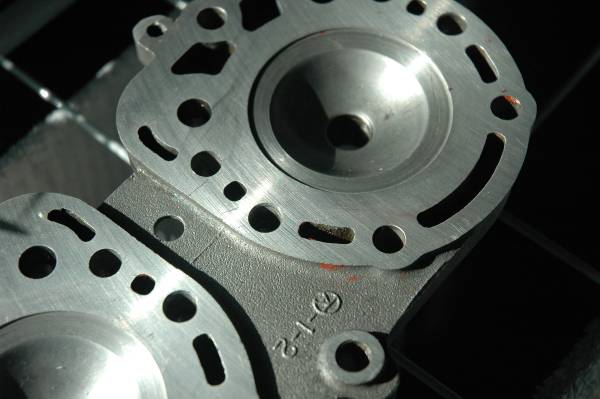

here is a picture from the "new" head.

is it possible that the surface is to rough??

with the fingernails i can feel the grooves

dirk

Posted: Sun Oct 12, 2008 12:59 am

by JanBros

dirk wrote:here is a picture from the "new" head.

is it possible that the surface is to rough??

with the fingernails i can feel the grooves

dirk

I'd say yes

Posted: Sun Oct 12, 2008 12:21 pm

by the-elf

I would also agree that its too rough. sand it down with a sheet of wet and dry stuck to a piece of glass or another suitable and flat surface.

I had a head machined ages ago and had simular problems, turned out that the head wasn't held down correctly while being machined and had flexed. I had to then polish the head flat again.

Posted: Sun Oct 12, 2008 8:44 pm

by kwackman12

Dirk as far as i'm aware you shoulde'nt use silicone sealer on head gaskets, You should use a sealent like "Blue Hylomar" or perhaps someone else can sugest something different

Posted: Sun Oct 12, 2008 9:44 pm

by dirk

hi

ok

I'll try it with a sheet of wet and dry and "Hylomar".

but "Dirko HT" is here the best friend for any leakage.

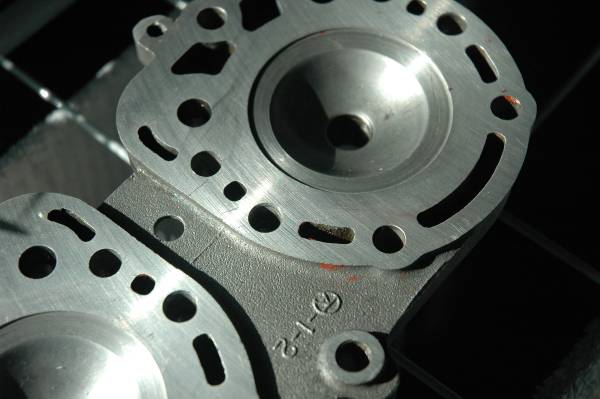

here a picture with more distance,

sure looks it not so bad as the first picture, but you can see the groves.

Dirk

Posted: Sun Oct 12, 2008 10:00 pm

by dirk

is it possible, after the head is machined, that the pins (guide sleeves) are too long?

Posted: Mon Oct 13, 2008 1:27 pm

by the-elf

dirk wrote:is it possible, after the head is machined, that the pins (guide sleeves) are too long?

Unless there is some thing in the holes stopping the dowels seating then no. For the cost you could always get some new one's, from memory they only cost a few pence each.

Posted: Tue Oct 28, 2008 11:11 pm

by dirk

Hi

a friend of me inspected the head again.

the head was not flat (0,08mm) and the surface a little bit too rough.

however

machined again (0.1mm) and now the head is flat with a clean surface.

barrels detached.

torque down the head with new dry genuine gasket in many tours.

than torque down the barrels.

Squish clearance now 0.9mm

run the bike 130km and no leak!

torque down the head and barrels again.

That's that!

Dirk

Posted: Tue Oct 28, 2008 11:22 pm

by scooble

glad to hear that you got it all sorted, it feels good when it all comes together. Its the little things like that which make a good reliable engine.